Pavement Preservation

The Importance of Timely Maintenance

Asphalt pavements deteriorate in many ways. Infrared rays from the sun cause the semi-solid asphalt particles to harden and become brittle. Cold temperatures cause the asphalt mat to contract creating thermal cracks. Over time, cyclic temperature changes lead to block cracking. Moisture induced damage will also cause the pavement to deteriorate over time.

Chip Seals

By minimizing raveling and sealing minor cracks, chip seals extend the life of the pavement by creating a new wearing surface.

Chip seals are a cost-effective pavement preservation tool used on roads with high and low traffic volumes. Chip seals are used to enhance skid resistance, slow oxidation and minimize water intrusion to protect the underlying pavement. Chip seal binders can be polymer modified as well to improve aggregate retention and provide for a quicker return to traffic.

Micro Surfacing

Micro surfacing is a preventative and corrective surface treatment that provides a new wearing surface to extend the life of pavements in good condition.

Micro surfacing provides skid resistance, prevents moisture intrusion, protects the pavement from further oxidation and restores the uniform black appearance. On a stable, well-prepared asphalt pavement, micro surfacing is uniformly spread with specialized equipment. It is the most economical choice when leveling or rut filling is required. Micro surfacing boasts quick construction times and minimal disruption to the traveling public.

Slurry Seals

Slurry seal boasts quick construction times and reasonable disruption to the traveling public.

Slurry seal is a surface treatment designed to extend the life of asphalt pavements in good condition by providing skid resistance, restricting moisture intrusion, protecting the structure from further oxidation and raveling, and restoring a uniform black appearance.

Pavement Deterioration

Pavements can also deteriorate through loading.

This is usually a concern on high volume arterial routes and highways that accommodate heavy vehicles (with 18,000 pound axle loads). Lighter vehicles (cars, pickups and SUVs) have an insignificant role in the load induced deterioration of the pavement.

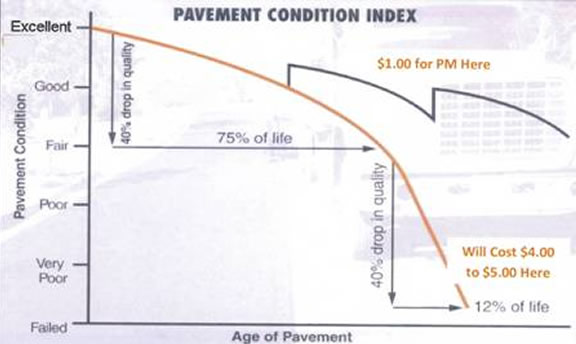

As an asphalt street ages it remains in good condition for about 70% of its life. After that the pavement deteriorates at a rapid rate. Many pavement managers time their maintenance treatments to coincide with the “Treatment Triggers” shown on the following curve. By applying a low cost surface treatment on a street when it is still in fairly good condition an agency can realize significant savings in lieu of waiting for the pavement to deteriorate to the point when it needs to be paved or reconstructed.

The chart shows that for every dollar spent on preventative maintenance it will cost four to five times that amount to pave or reconstruct the same road segment.

A proportional maintenance approach allows you more flexibility in programming and is more cost effective. By investing some funds on streets in fair condition you prevent further deterioration and more costly repairs. By overlaying some roads and surface treating others you can significantly reduce the number of roads in your network that are in poor condition.